Microprocessor Designs is an electrical engineering and product design development company located in beautiful Shelburne, VT. The group was founded in 1987 and specializes in embedded microcomputer based product design and development from concept through completion. We provide hardware, firmware, software and manufacturing design services for clients throughout the US.

PROJECTS

https://www.updesigns.com/wp-content/uploads/2018/03/contro1.gif

357

551

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-14 18:16:462019-07-03 13:16:48LPA Design – PocketWizard ControlTL Products

https://www.updesigns.com/wp-content/uploads/2018/03/contro1.gif

357

551

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-14 18:16:462019-07-03 13:16:48LPA Design – PocketWizard ControlTL Products https://www.updesigns.com/wp-content/uploads/2018/02/StirlingEngineLG.jpg

250

192

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-13 20:06:212019-07-03 12:47:07DEKA R&D – Stirling Engine Controller

https://www.updesigns.com/wp-content/uploads/2018/02/StirlingEngineLG.jpg

250

192

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-13 20:06:212019-07-03 12:47:07DEKA R&D – Stirling Engine Controller https://www.updesigns.com/wp-content/uploads/2018/07/PowerFoot1.jpg

728

627

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-09 16:16:272019-07-03 12:47:54Iwalk/Biom – Powered Ankle System

https://www.updesigns.com/wp-content/uploads/2018/07/PowerFoot1.jpg

728

627

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-09 16:16:272019-07-03 12:47:54Iwalk/Biom – Powered Ankle System https://www.updesigns.com/wp-content/uploads/2018/07/Riddell-Insite-System.jpg

412

618

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-08 15:41:042019-07-03 12:49:15Riddell – Insite Impact Response System

https://www.updesigns.com/wp-content/uploads/2018/07/Riddell-Insite-System.jpg

412

618

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-08 15:41:042019-07-03 12:49:15Riddell – Insite Impact Response System https://www.updesigns.com/wp-content/uploads/2018/03/index.1.jpg

440

615

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

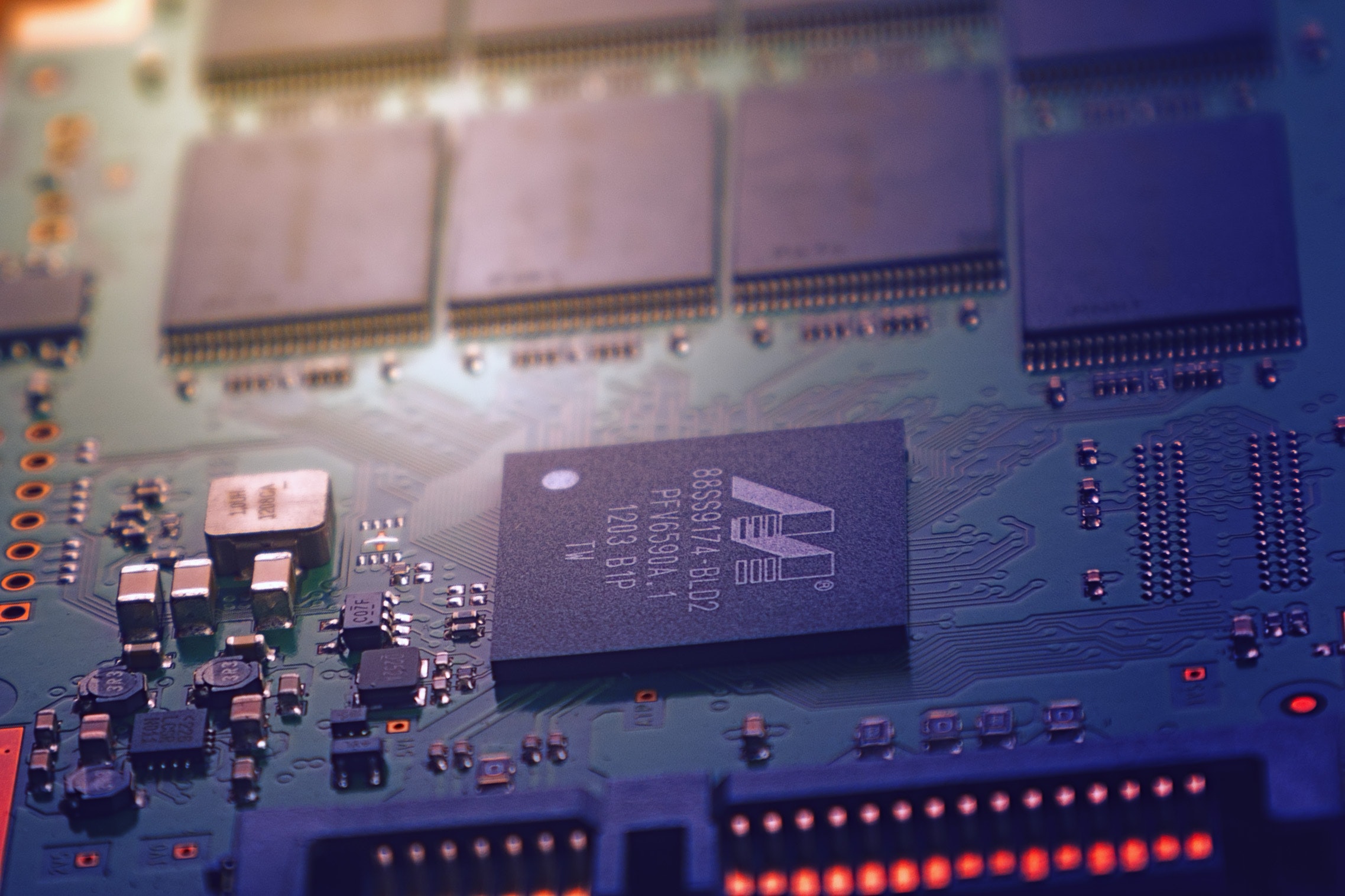

updesign2018-03-05 18:06:002019-07-03 12:46:27DARPA – Revolutionizing Prosthetics 2009 Finger Tip Sensor

https://www.updesigns.com/wp-content/uploads/2018/03/index.1.jpg

440

615

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-05 18:06:002019-07-03 12:46:27DARPA – Revolutionizing Prosthetics 2009 Finger Tip Sensor https://www.updesigns.com/wp-content/uploads/2018/03/Power-Donut-Battery-Powered.jpg

336

422

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-04 18:13:542019-07-03 12:51:31USi – Power-Donut

https://www.updesigns.com/wp-content/uploads/2018/03/Power-Donut-Battery-Powered.jpg

336

422

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-04 18:13:542019-07-03 12:51:31USi – Power-Donut https://www.updesigns.com/wp-content/uploads/2018/03/DEKA-Dialysis-Cropped.jpg

240

240

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-03 18:32:402019-07-03 15:10:13DEKA R&D – Home Choice Dialysis

https://www.updesigns.com/wp-content/uploads/2018/03/DEKA-Dialysis-Cropped.jpg

240

240

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-03 18:32:402019-07-03 15:10:13DEKA R&D – Home Choice Dialysis https://www.updesigns.com/wp-content/uploads/2018/03/prounit1.jpg

206

176

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-02 18:25:312019-07-03 15:03:18Segway – Human Transport System Design

https://www.updesigns.com/wp-content/uploads/2018/03/prounit1.jpg

206

176

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-02 18:25:312019-07-03 15:03:18Segway – Human Transport System Design https://www.updesigns.com/wp-content/uploads/2018/07/SRAM-E-Matic-Assembly-1.jpg

624

624

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-02 17:29:332019-07-03 12:58:06SRAM – Ematic Electric Bike Hub

https://www.updesigns.com/wp-content/uploads/2018/07/SRAM-E-Matic-Assembly-1.jpg

624

624

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-02 17:29:332019-07-03 12:58:06SRAM – Ematic Electric Bike Hub https://www.updesigns.com/wp-content/uploads/2018/07/Small-6mm-stepper-motor.jpg

150

200

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-01 19:26:082019-07-03 15:15:34Parker Hannifin – Motor Control

https://www.updesigns.com/wp-content/uploads/2018/07/Small-6mm-stepper-motor.jpg

150

200

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-01 19:26:082019-07-03 15:15:34Parker Hannifin – Motor Control https://www.updesigns.com/wp-content/uploads/2020/12/Desktop-Metal-Studio-Printer-001-scaled-down.jpg

280

302

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-01 18:30:322020-12-21 19:49:56Desktop Metal – 3D Studio Printer

https://www.updesigns.com/wp-content/uploads/2020/12/Desktop-Metal-Studio-Printer-001-scaled-down.jpg

280

302

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-01 18:30:322020-12-21 19:49:56Desktop Metal – 3D Studio Printer https://www.updesigns.com/wp-content/uploads/2018/03/pm5-cropped.jpg

126

119

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-01 18:23:542018-10-16 15:36:18Concept2 PM3, PM4 and PM5 Monitors

https://www.updesigns.com/wp-content/uploads/2018/03/pm5-cropped.jpg

126

119

updesign

https://www.updesigns.com/wp-content/uploads/2018/08/Logo_Transparent-300x60.png

updesign2018-03-01 18:23:542018-10-16 15:36:18Concept2 PM3, PM4 and PM5 MonitorsClick here to add your own text